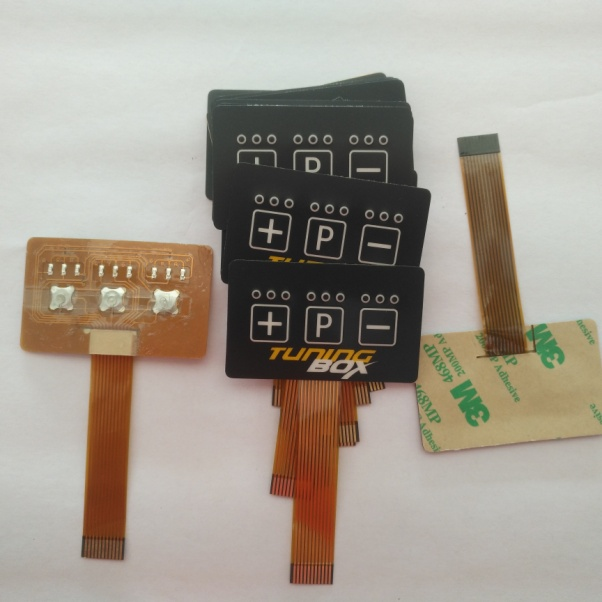

When the panel is not pressed, the membrane switch is in the normal state, its upper and lower contacts are disconnected, and the isolation layer acts as an isolation for the upper and lower lines; When the panel is pressed, the contact of the upper circuit deforms downward, coincides with the lower circuit and makes the circuit conductive. The conductive circuit sends a signal to the external connecting instrument (substrate), so as to realize its corresponding function; When the finger is released, the upper circuit contact bounces back, the circuit is disconnected, and the circuit triggers a signal

www.fpc-switch.com mail:xinhui@xinhuiok.com si4863@163.com

Inspection steps of membrane switch

1. Material inspection: panel, substrate, silver paste, carbon ink, spacer, adhesive, adhesive, reinforcing plate and insulation printing shall comply with the provisions of the drawing.

2. Shape comparison: the shape, conductor circuit, insulation treatment, lining plate combination, etc. shall comply with the provisions of the drawing or provide physical samples.

3. Check the color: use the visual method to compare with the sample or color card to see if there is color difference. If the color requirements are particularly strict, use the color difference meter to compare.

4. Peel strength test: the peel strength of the adhesive shall not be less than 8N / 25mm.

5. Adhesion inspection of ink: the ink is attached with transparent tape and pressed by hand to ensure that there are no bubbles. It will peel off quickly after 10 seconds, and there shall be no ink falling. After the insulating ink is dry, stick the ink surfaces against each other, and then after heavy pressing for 24 hours, it is necessary to ensure that the insulating surfaces do not stick to each other. Apply pressure-sensitive adhesive tape and press it without bubbles for 1 minute. Peel it quickly without ink falling off.

6. Check the dimension: the allowable range of tolerance not indicated in the drawing shall comply with the standard, and the rest shall comply with the provisions of the drawing.

7. Check the appearance: the panel shall not have obvious defects, such as missing strokes of characters; Stain and light transmission spot; Deinking, stain and scratch; Overflow and residual glue of transparent window. There is no offset phenomenon, such as printing overprint, up and down line key position combination, line and key piece, panel and key combination, bubbling and substrate at panel keys. The size of stamping burr and extrusion bending shall not be greater than 0.2mm, and the position shall face the side without conductor.

8. Bubble detection of membrane switch: equal height and balanced strength. Plane type: 57 ~ 284g force, touch feeling: 170 ~ 397G force.

-www.fpc-switch.com mail:xinhui@xinhuiok.com si4863@163.com

————————————————————————-

Membrane switch structure

1、 Panel layer

The panel layer is generally made by silk printing exquisite patterns and words on colorless transparent sheets such as pet and PC less than 0.25mm. Because the main function of the panel layer is to mark and press keys, the selected materials must have the characteristics of high transparency, high ink adhesion, high elasticity and high toughness.

2、 Surface adhesive layer

The main function of surface glue is to closely connect the panel layer with the circuit layer to achieve the effect of sealing and connection. Generally, the thickness of this layer is required to be between 0.05-0.15mm, with high viscosity and anti-aging; In production, special film switch double-sided adhesive tape is generally selected. Some film switches are required to be waterproof and high-temperature proof, so the surface adhesive must also use materials of different properties according to needs.

3、 Upper and lower layers of control circuit

This layer adopts polyester film (PET) with good performance as the carrier of switch circuit graphics, and uses special process silk screen to print conductive silver paste and conductive carbon paste on it to make it have conductive properties. Its thickness is generally within 0.05-0.175mm, and 0.125mm pet is the most common.

4、 Adhesive layer

It is located between the upper circuit and the lower circuit layer and plays the role of sealing and connection. Generally, pet double-sided adhesive is used, and its thickness ranges from 0.05 to 0.2mm; When selecting the material of this layer, the overall thickness, insulation, hand feel and sealing of the circuit key package shall be fully considered.

5、 Back adhesive layer

The use of back glue is closely related to the material of membrane switch. Common double-sided adhesive, 3M adhesive, waterproof adhesive, etc. are often used.

www.fpc-switch.com mail:xinhui@xinhuiok.com si4863@163.com

Post time: Mar-21-2022