Low price for Film Button Switch - Membrane switch KEY – Xinhui

Low price for Film Button Switch - Membrane switch KEY – Xinhui

Low price for Film Button Switch - Membrane switch KEY – Xinhui Detail:

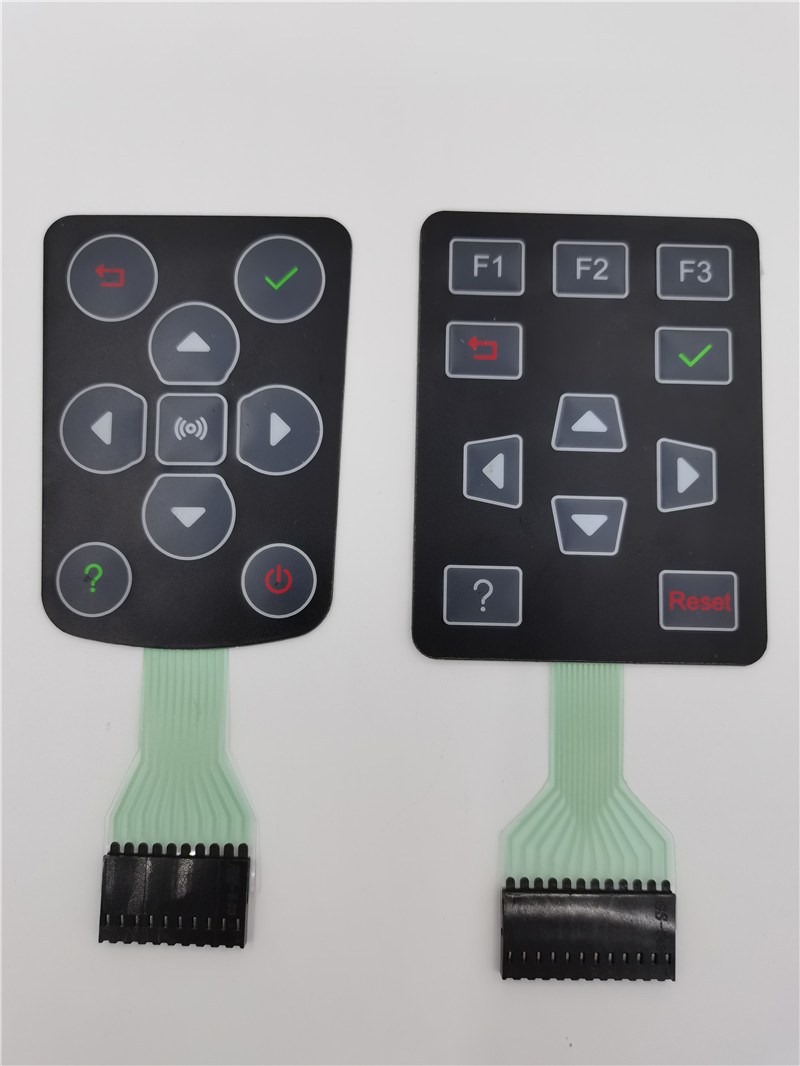

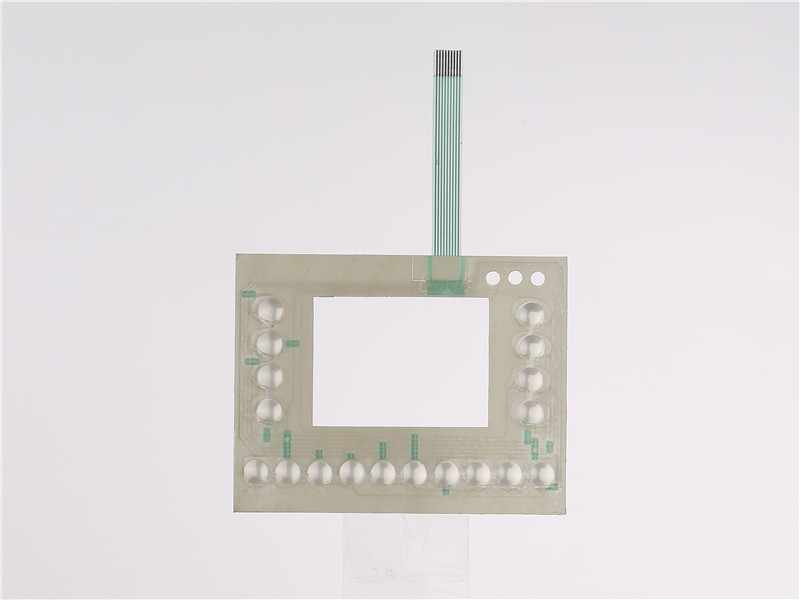

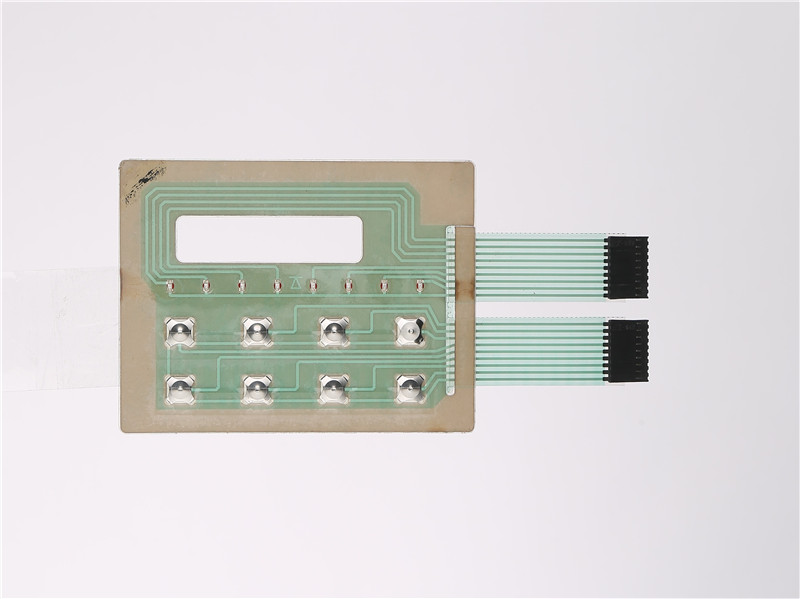

Three-dimensional membrane switch

Usually, the buttons on the membrane switch only use colors to express the position, shape and size of the key body. In this way, the accuracy of the operation can only be recognized by the operator’s vision. Since there is no appropriate feedback information to indicate whether the finger is pressed in the effective range of the switch to make the switch act,

As a result, the confidence in the monitoring of the whole machine and the speed of operation are affected. A kind of membrane switch that makes the switch key body slightly protrude, slightly higher than the panel to form a three-dimensional shape, is called a three-dimensional key switch. The three-dimensional key can not only accurately specify the range of the key body, improve the recognition speed, make the operator’s touch more sensitive, but also enhance the decorative effect of the product appearance. The production of the three-dimensional key must be done in the design stage of the panel Arrangement, with process holes for precise positioning during mold pressing, and the height of the three-dimensional protrusions should generally not exceed twice the thickness of the substrate. In order to beautify the appearance of the product, the protrusions of the raised membrane switch can be made in many variations, and must be arranged in the design stage of the panel, with craft holes in order to have precise positioning when the mold is pressed, and its three-dimensional convex The height of the lift should generally not exceed twice the thickness of the substrate. For the appearance of beautiful products, the protrusions of the raised membrane switch can be changed in many ways.

Related Parameters

| Membrane switch parametersameters | ||

| Electronic properties | Working voltage:≤50V(DC) | Working current:≤100mA |

| Contact resistance:0.5~10Ω | Insulation resistance:≥100MΩ(100V/DC) | |

| Substrate pressure resistance:2kV(DC) | Rebound time:≤6ms | |

| Loop resistance: 50 Ω, 150 Ω, 350 Ω, or determined according to the user’s needs. | Insulation ink withstand voltage:100V/DC | |

| mechanical propertiesti | Reliability service life:>One million times | Closure displacement: 0.1 ~ 0.4mm (tactile type) 0.4 ~ 1.0mm (tactile type) |

| Working force: 15 ~ 750g | Migration of conductive silver paste: at 55 ℃, temperature 90%, after 56 hours, it is 10m Ω / 50VDC between two wires | |

| There is no oxidation and impurity on the silver paste line | The line width of silver paste is greater than or equal to 0.3mm, the minimum interval is 0.3mm, the rough edge of line is less than 1 / 3, and the line gap is less than 1 / 4 | |

| Pin spacing standard 2.54 2.50 1.27 1.25mm | The bending resistance of outgoing line is 80 times with d = 10 mm steel rod. | |

| Environmental parametersme | Operating temperature:-20℃~+70℃ | Storage temperature: – 40 ℃ ~ + 85 ℃, 95% ± 5% |

| Atmospheric pressure:86~106KPa | ||

| Printing index index | The printing size deviation is ± 0.10 mm, the outline side line is not clear, and the weaving error is ± 0.1 mm | The chromatic deviation is ± 0.11mm/100mm, and the silver paste line is completely covered by the insulating ink |

| No ink scattered, no incomplete handwriting | The color difference is not more than two levels | |

| There shall be no crease or paint peeling | The transparent window shall be transparent and clean, with uniform color, without scratches, pinholes and impurities. | |

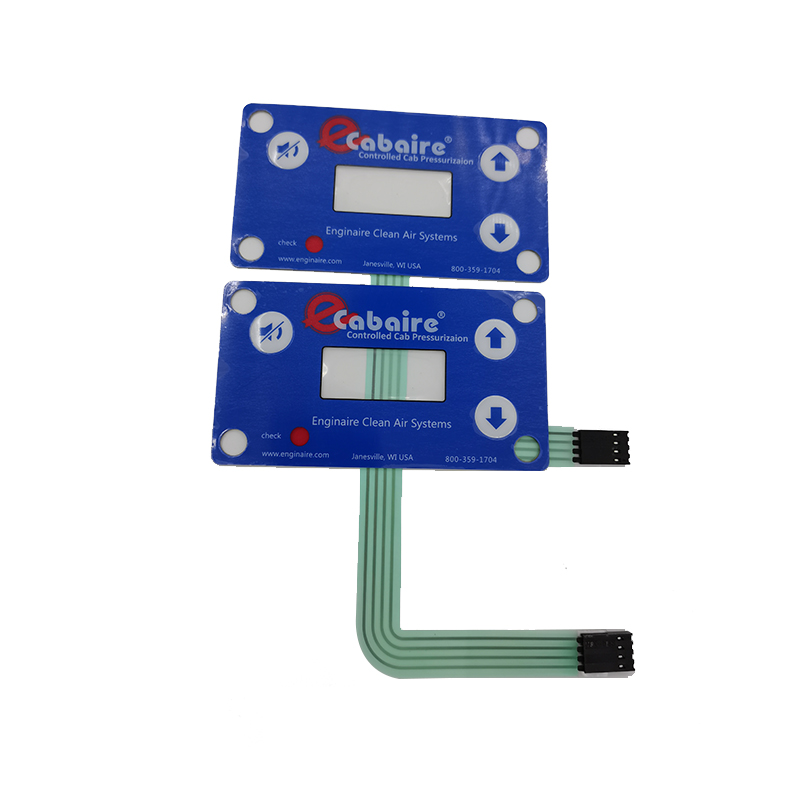

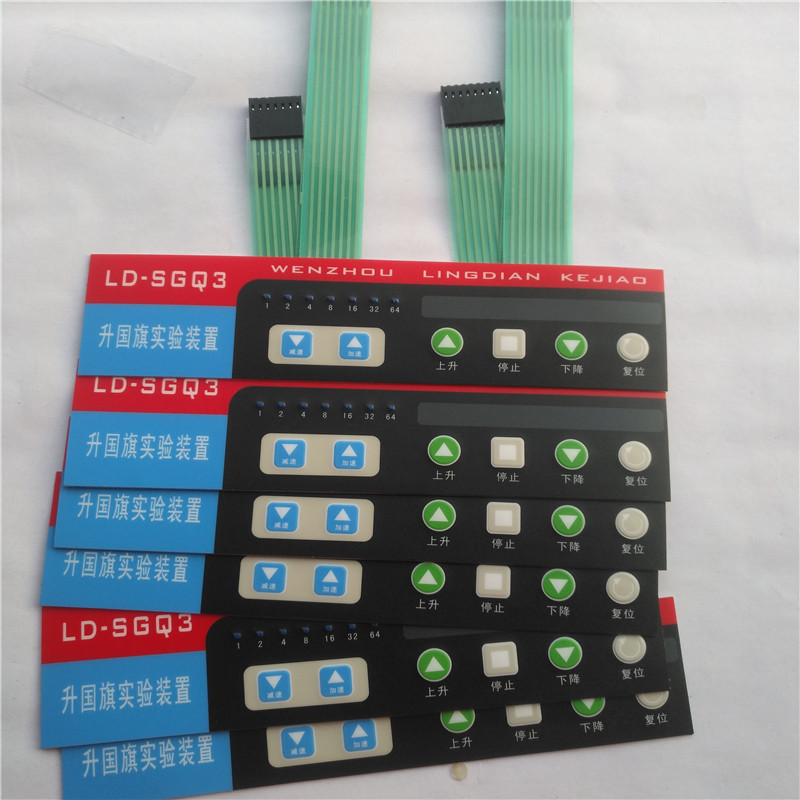

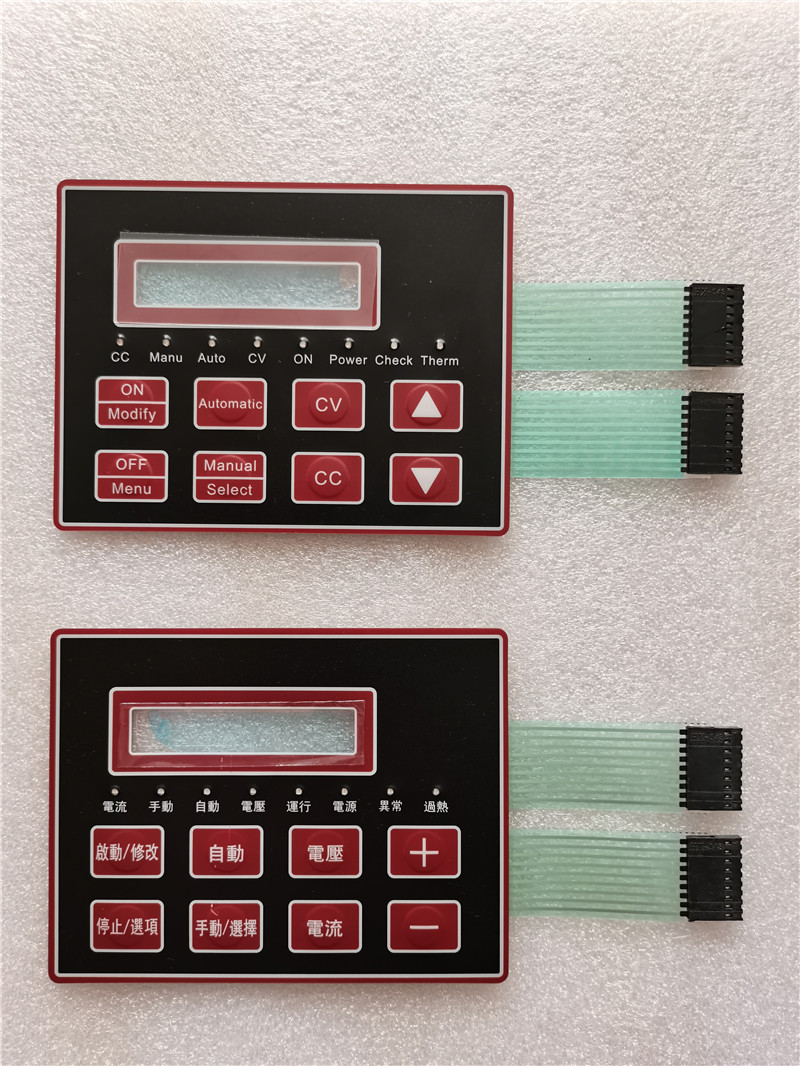

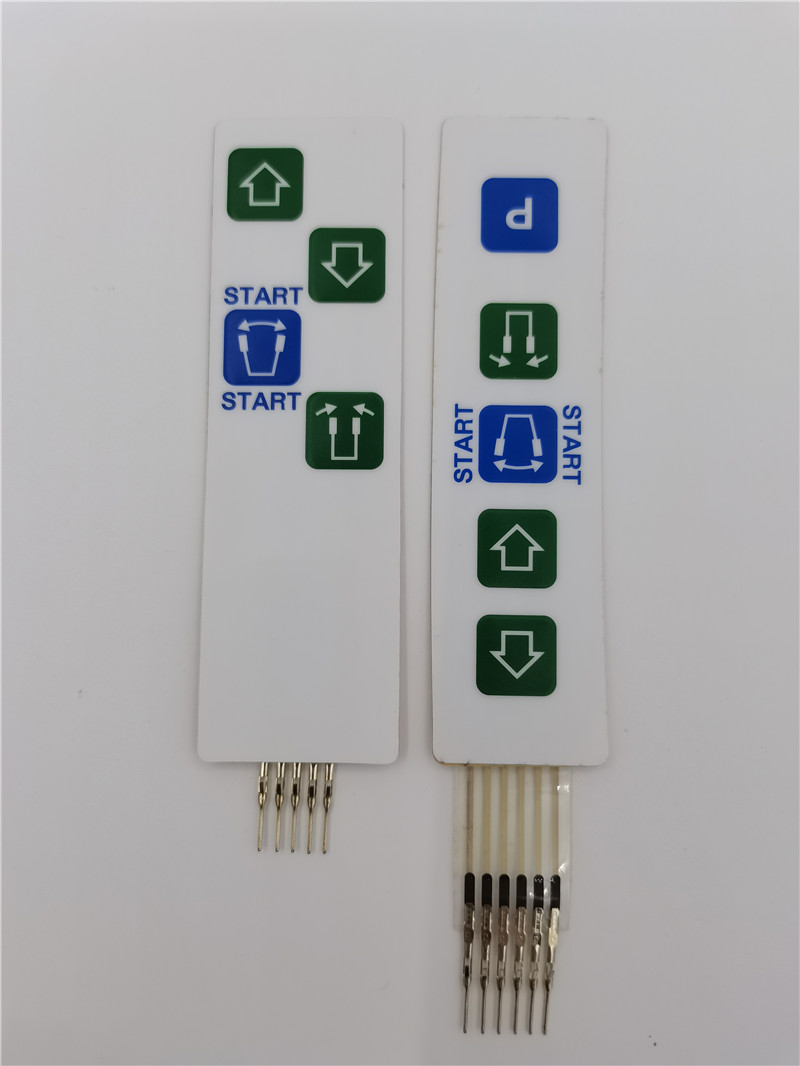

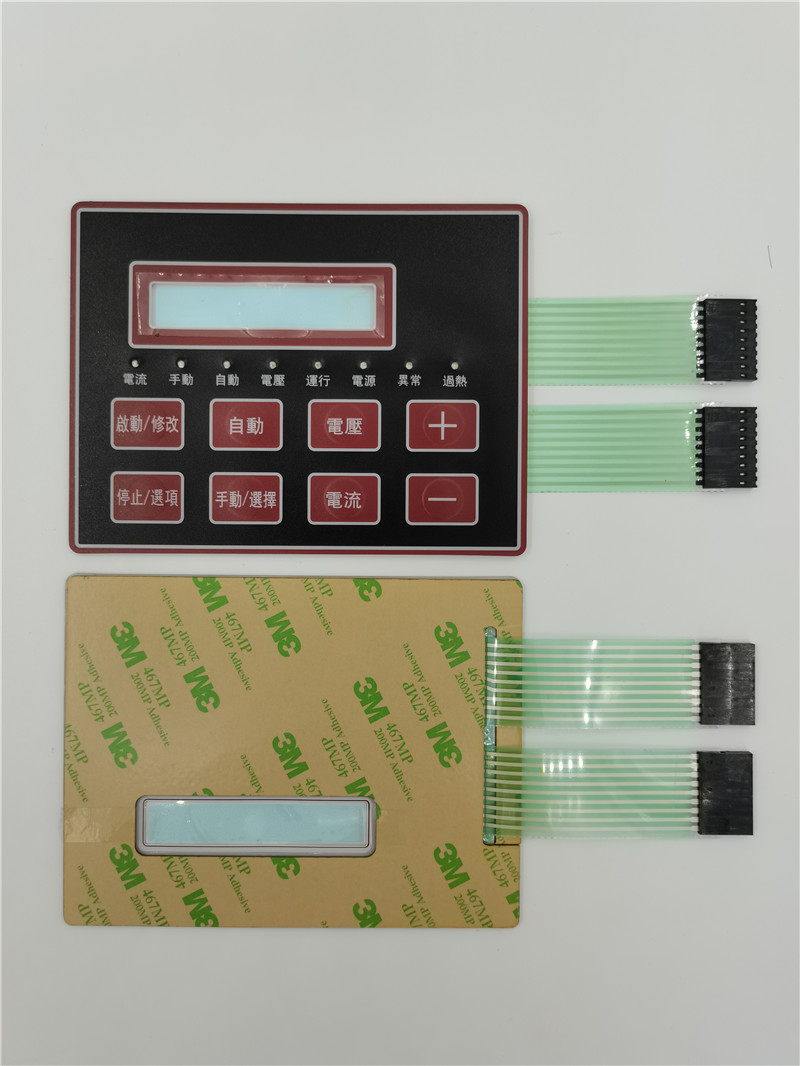

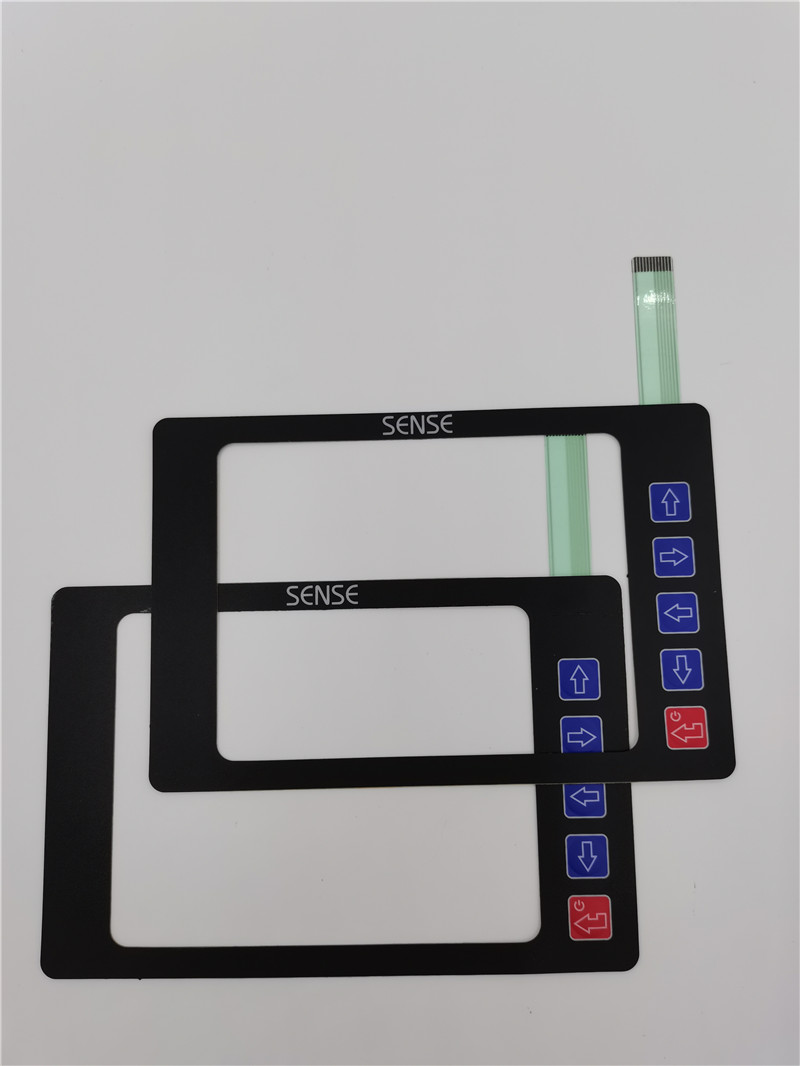

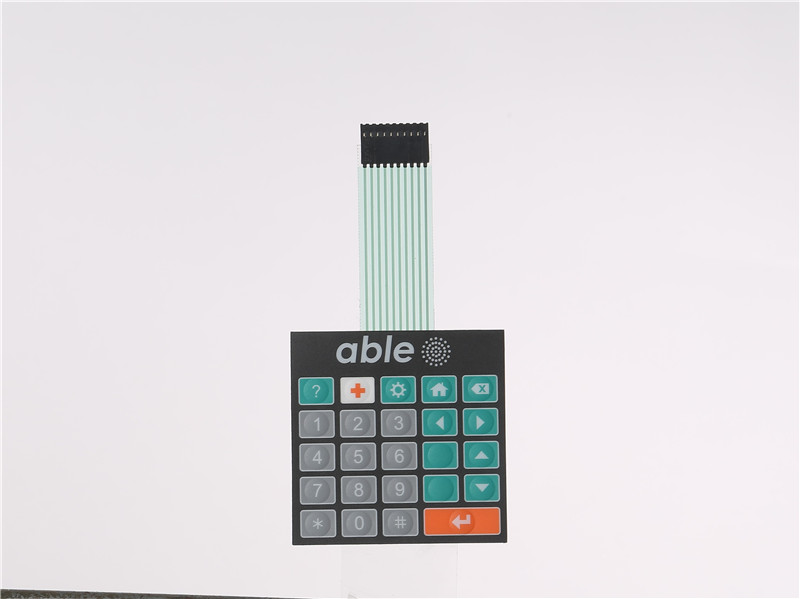

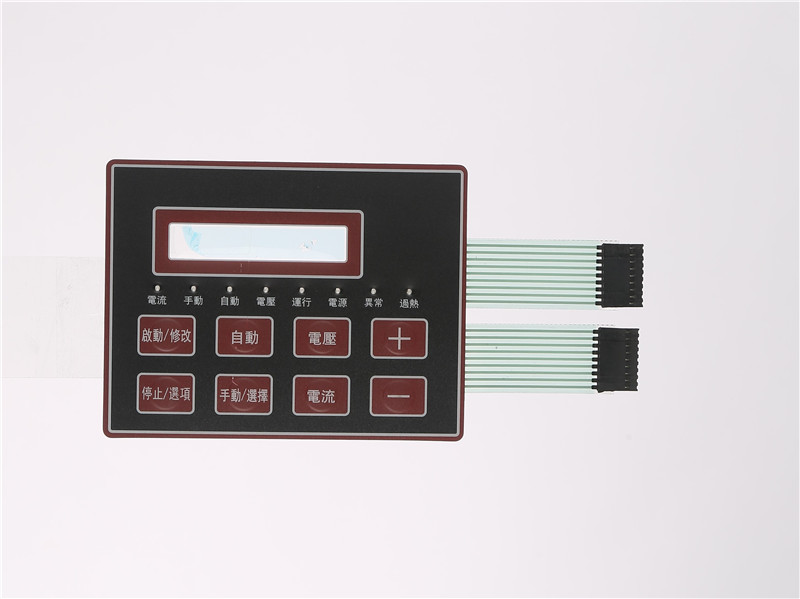

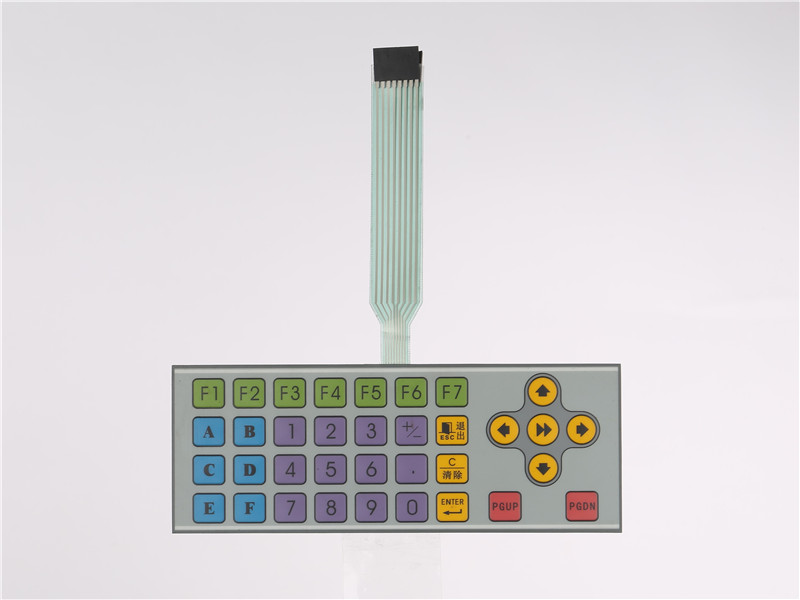

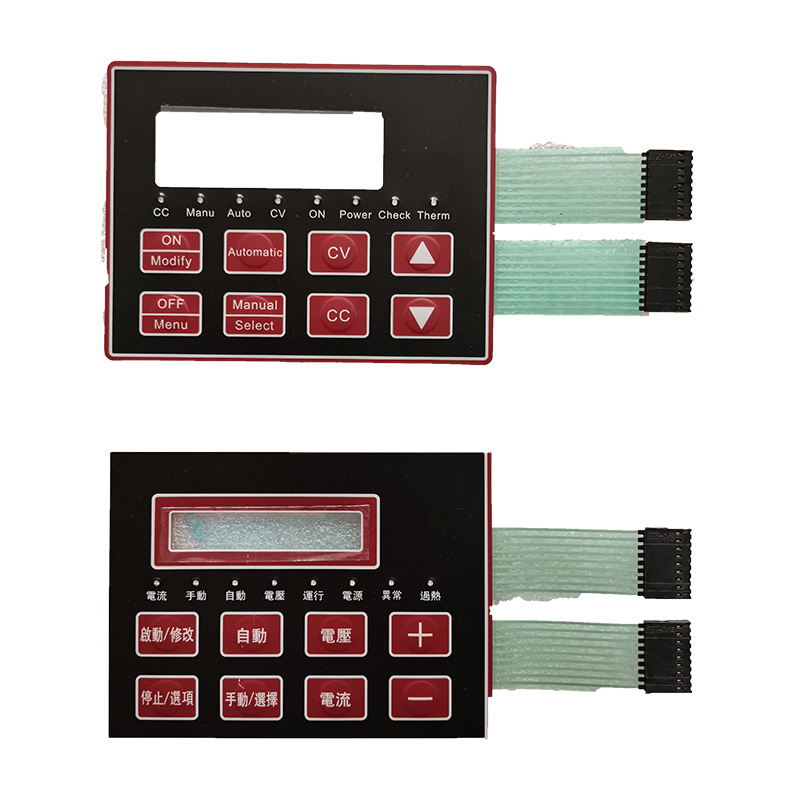

Product Show

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Low price for Film Button Switch - Membrane switch KEY – Xinhui , The product will supply to all over the world, such as: Roman, America, Greece, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.