High Quality Fpc Induction Button - FPC(FlexiblePrintedCircuit, FPC) – Xinhui

High Quality Fpc Induction Button - FPC(FlexiblePrintedCircuit, FPC) – Xinhui

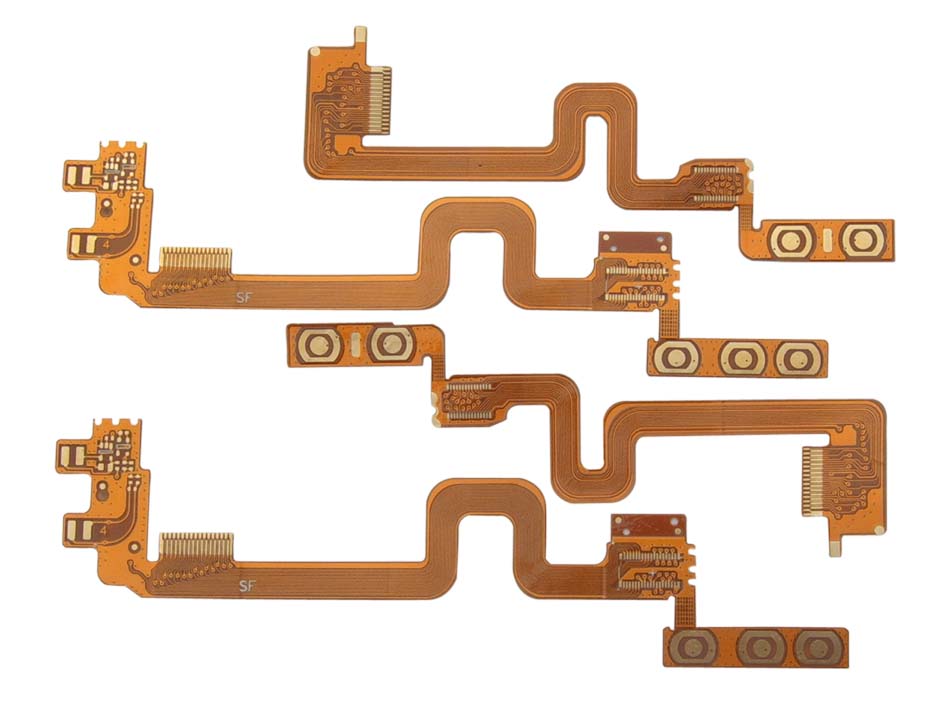

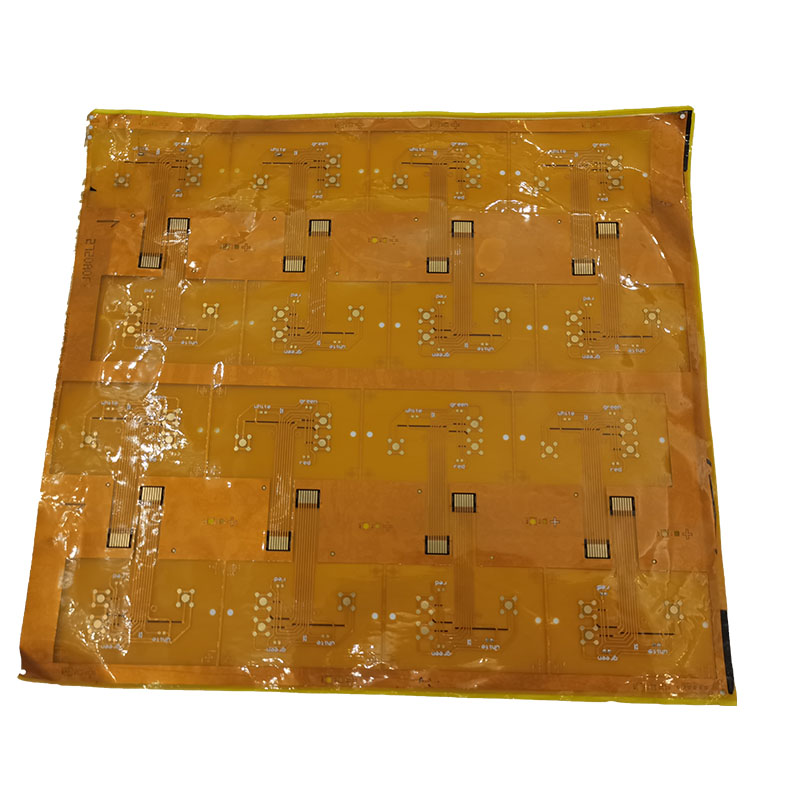

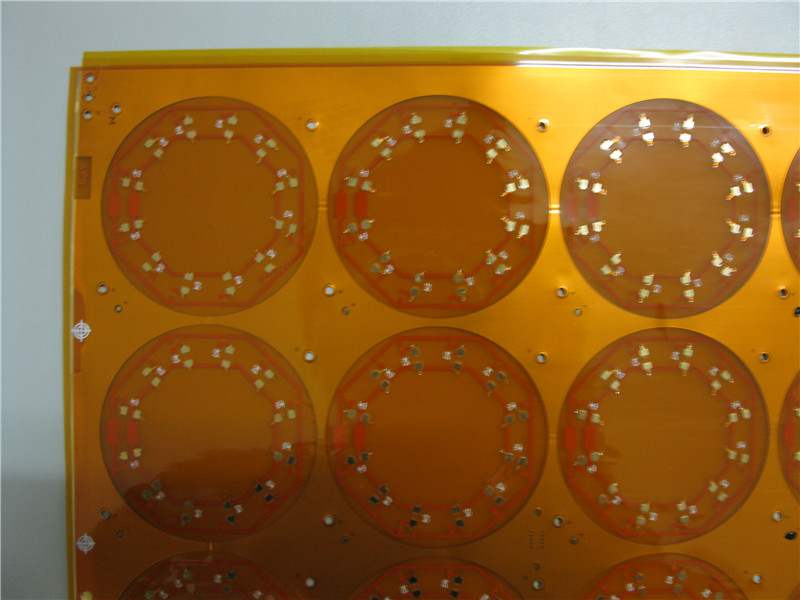

High Quality Fpc Induction Button - FPC(FlexiblePrintedCircuit, FPC) – Xinhui Detail:

FPC product description

Flexible circuit (FPC) is a technology developed by the United States for the development of space rocket technology in the 1970s. It is made of polyester film or polyimide as a substrate with high reliability and excellent flexibility. By embedding a circuit design on a thin and light plastic sheet that can be bent, a large number of precision components are stacked in a narrow and limited space to form a bendable flexible circuit. This kind of circuit can be bent at will, folded, light weight, small size, good heat dissipation, easy installation, and breaks through the traditional interconnection technology. In the structure of the flexible circuit, the materials are insulating film, conductor and adhesive.

Basic structure

Copper Film

Copper foil: basically divided into electrolytic copper and rolled copper. The common thickness is 1oz 1/2oz and 1/3 oz

Substrate film: There are two common thicknesses: 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Cover Film

Cover film protection film: for surface insulation. Common thicknesses are 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing; easy to work.

Stiffener Film (PI Stiffener Film)

Reinforcement board: Reinforce the mechanical strength of FPC, which is convenient for surface mounting operations. The common thickness is 3mil to 9mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing.

EMI: Electromagnetic shielding film to protect the circuit inside the circuit board from outside interference (strong electromagnetic area or susceptible to interference area).

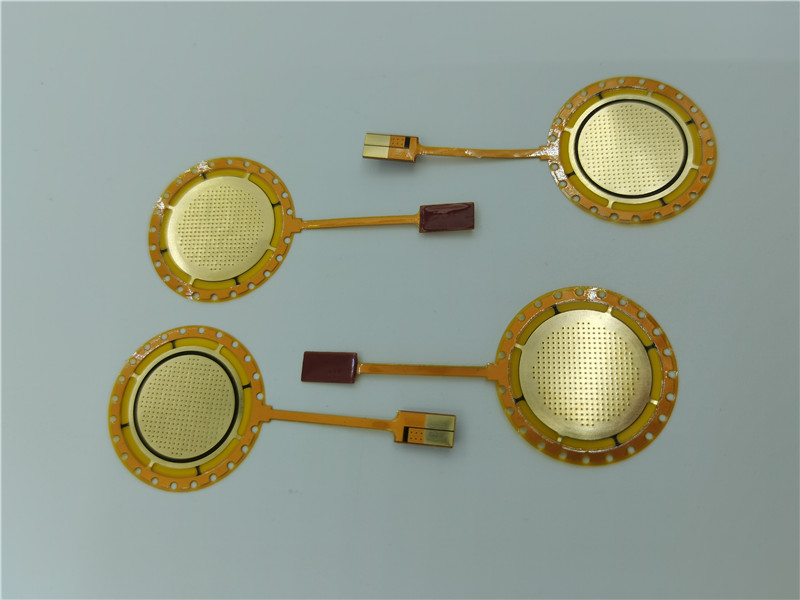

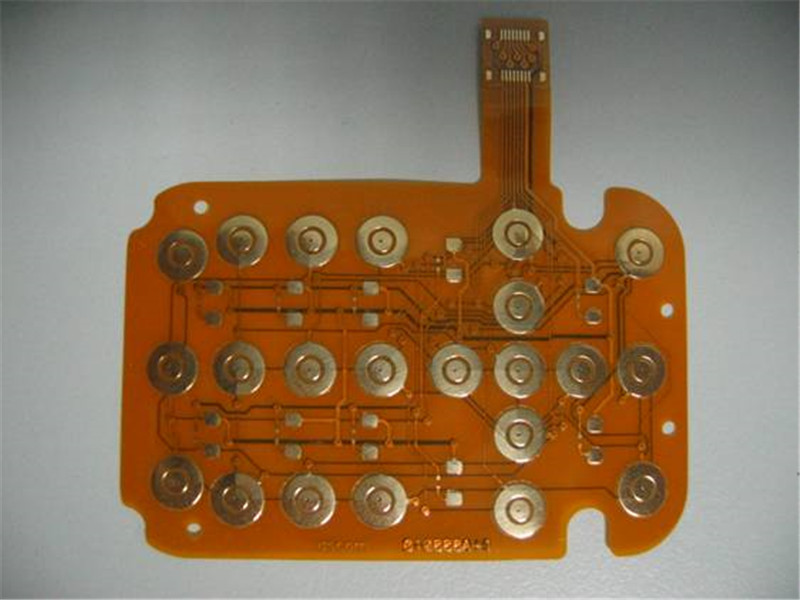

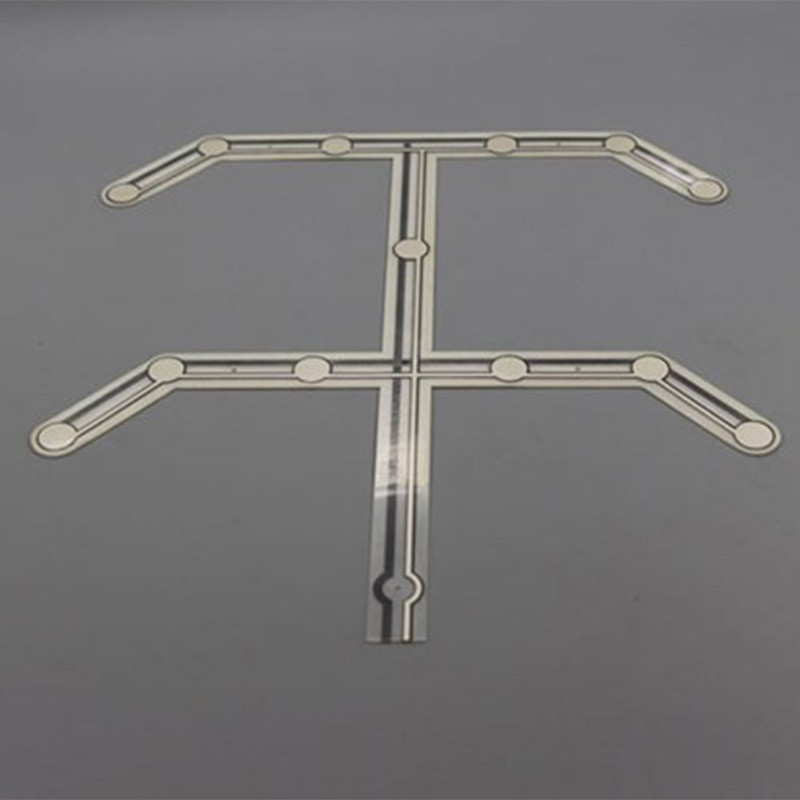

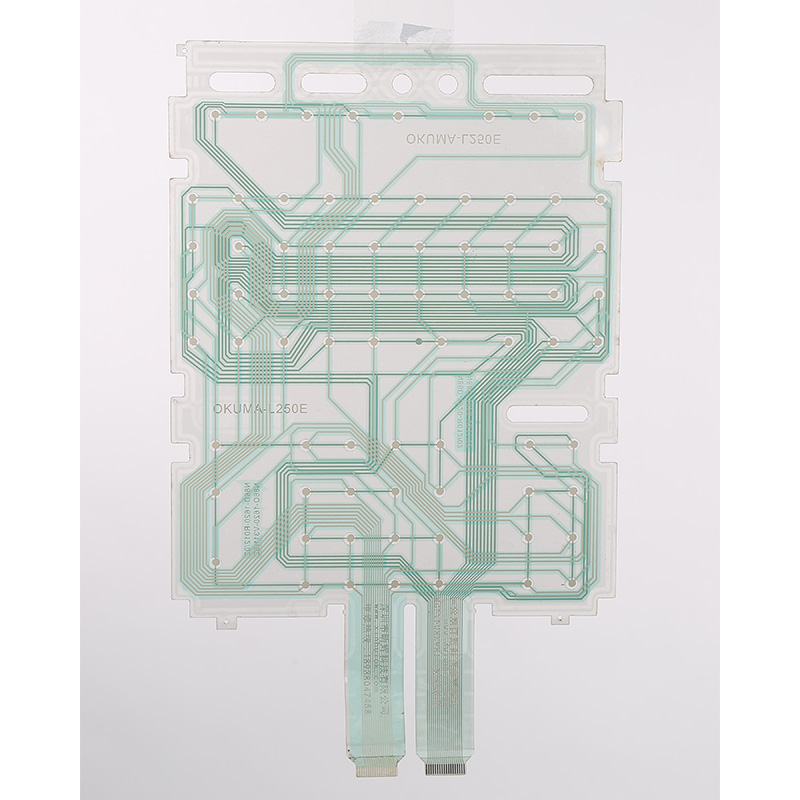

Product Show

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for High Quality Fpc Induction Button - FPC(FlexiblePrintedCircuit, FPC) – Xinhui , The product will supply to all over the world, such as: Mexico, Jamaica, Mecca, Our items have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll supply the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.