Free sample for Safety Pressure Switch - LGF membrane switch – Xinhui

Free sample for Safety Pressure Switch - LGF membrane switch – Xinhui

Free sample for Safety Pressure Switch - LGF membrane switch – Xinhui Detail:

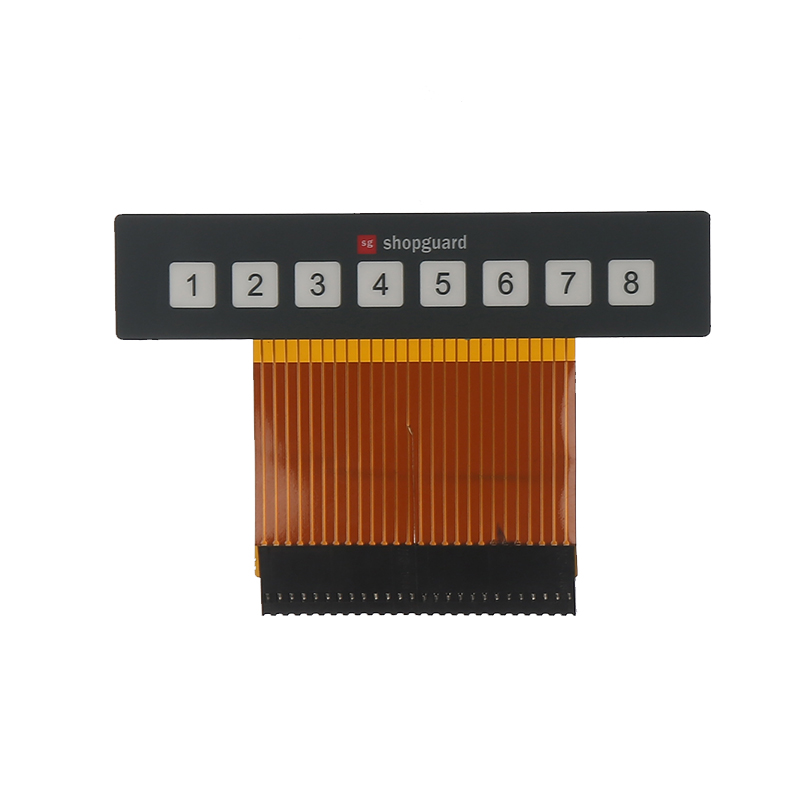

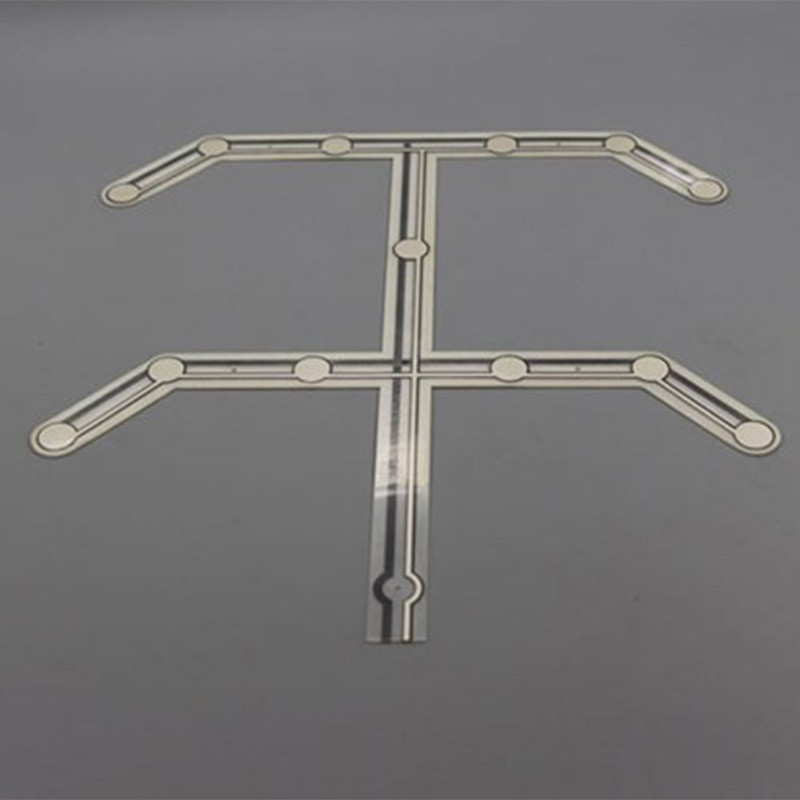

EL/LGF membrane switch

LGF membrane switches are usually used in office equipment, handheld instruments, industrial equipment, household appliances, and access control equipment. LGF membrane switches can make the keys light up, and the key content and logos can be clearly seen in the dark. Circuits usually use FPC or PCB, and side-light LEDs are needed to guide light through PC materials to make the light source more uniform and stable.

The EL light-emitting membrane switch is a mode in which the EL light-emitting sheet is placed on the lower layer of the panel and the upper layer of the switch circuit is printed. The light-transmitting area of the panel is printed, and the EL light needs to be designed with an EL driver IC for lighting.

To highlight the characters that need to be displayed. The user can clearly see the keyboard content in a dark environment.

Product related words: membrane switch, membrane key, membrane keyboard, FPC keyboard, PCB keyboard, electrical key membrane,

Toy membrane switch, capacitive touch switch, membrane control switch, medical circuit electrode sheet, waterproof membrane switch,

LGF luminous membrane switch, LED membrane keyboard, keyboard line switch, waterproof keyboard, membrane keyboard, ultra-thin switch button. Controller membrane switch

Related Parameters

| Membrane switch parametersameters | ||

| Electronic properties | Working voltage:≤50V(DC) | Working current:≤100mA |

| Contact resistance:0.5~10Ω | Insulation resistance:≥100MΩ(100V/DC) | |

| Substrate pressure resistance:2kV(DC) | Rebound time:≤6ms | |

| Loop resistance: 50 Ω, 150 Ω, 350 Ω, or determined according to the user’s needs. | Insulation ink withstand voltage:100V/DC | |

| mechanical propertiesti | Reliability service life:>One million times | Closure displacement: 0.1 ~ 0.4mm (tactile type) 0.4 ~ 1.0mm (tactile type) |

| Working force: 15 ~ 750g | Migration of conductive silver paste: at 55 ℃, temperature 90%, after 56 hours, it is 10m Ω / 50VDC between two wires | |

| There is no oxidation and impurity on the silver paste line | The line width of silver paste is greater than or equal to 0.3mm, the minimum interval is 0.3mm, the rough edge of line is less than 1 / 3, and the line gap is less than 1 / 4 | |

| Pin spacing standard 2.54 2.50 1.27 1.25mm | The bending resistance of outgoing line is 80 times with d = 10 mm steel rod. | |

| Environmental parametersme | Operating temperature:-20℃~+70℃ | Storage temperature: – 40 ℃ ~ + 85 ℃, 95% ± 5% |

| Atmospheric pressure:86~106KPa | ||

| Printing index index | The printing size deviation is ± 0.10 mm, the outline side line is not clear, and the weaving error is ± 0.1 mm | The chromatic deviation is ± 0.11mm/100mm, and the silver paste line is completely covered by the insulating ink |

| No ink scattered, no incomplete handwriting | The color difference is not more than two levels | |

| There shall be no crease or paint peeling | The transparent window shall be transparent and clean, with uniform color, without scratches, pinholes and impurities. | |

Product Show

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Free sample for Safety Pressure Switch - LGF membrane switch – Xinhui , The product will supply to all over the world, such as: Comoros, Tajikistan, Comoros, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.