Excellent quality Pi Film Heating - PI Heater Film(Thin film PCB) – Xinhui

Excellent quality Pi Film Heating - PI Heater Film(Thin film PCB) – Xinhui

Excellent quality Pi Film Heating - PI Heater Film(Thin film PCB) – Xinhui Detail:

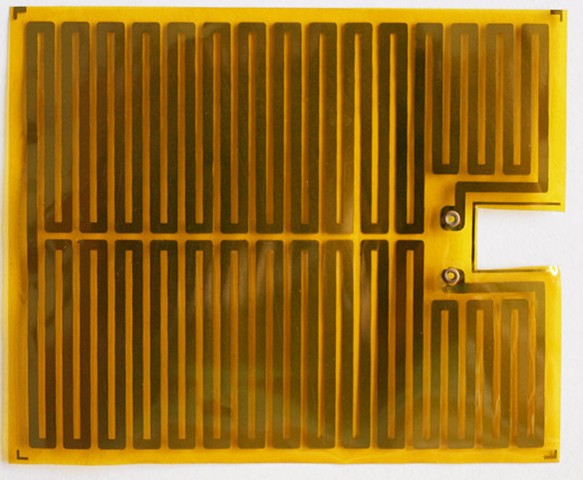

Features

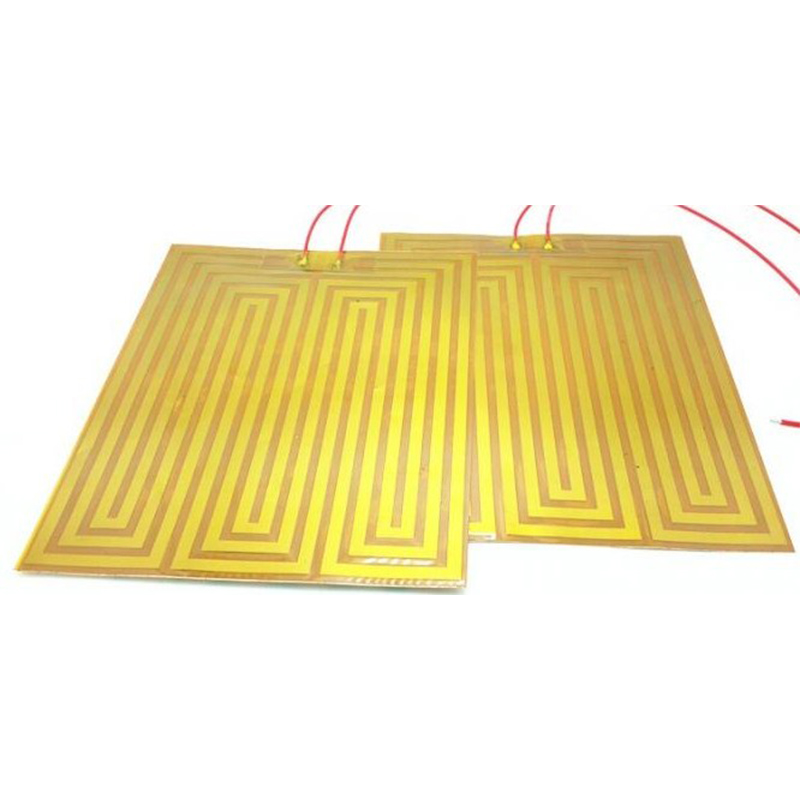

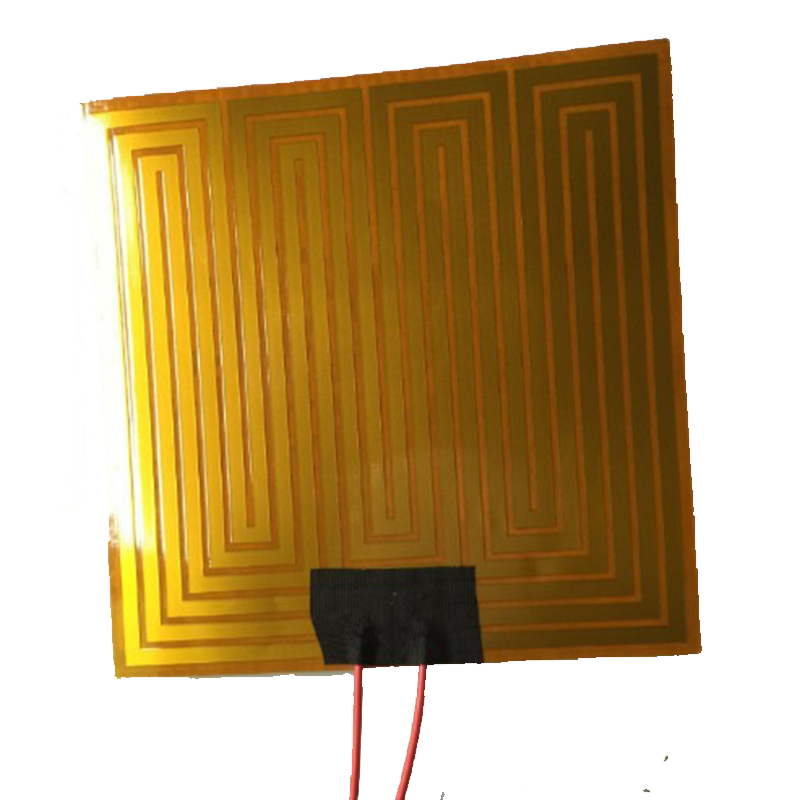

◆Good softness, flexibility, fast preheating speed and long service life.

◆Ultra-thin: the thickness is only 0.3mm, the surface is flat, the space is small, and the bending radius is about 5mm.

◆Various varieties: various small-area resistive circuit elements can be made.

◆Uniform heating: the circuit layout of the etching process is uniform, the thermal inertia is small, it is in close contact with the heated body, and the heating speed is fast.

◆Easy to install: with double-sided tape, it can be directly pasted on the surface of the heated body.

◆Long life: flat design, low power load compared to other heating wire heaters, and long service life. Good insulation.

◆ High temperature and high pressure test: It can be used for a long time at 200℃. And passed the 1500V high voltage test.

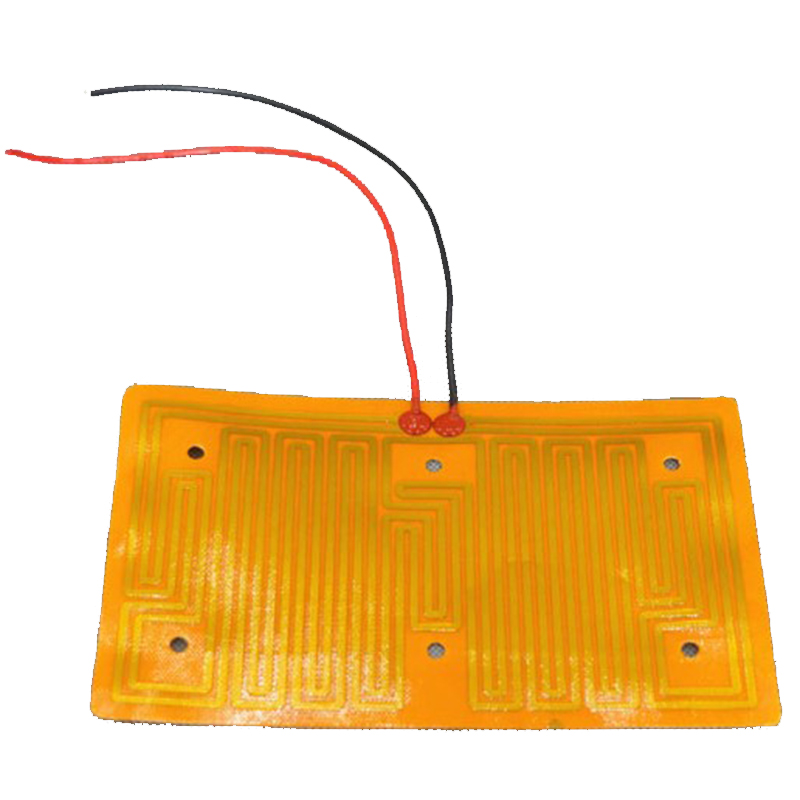

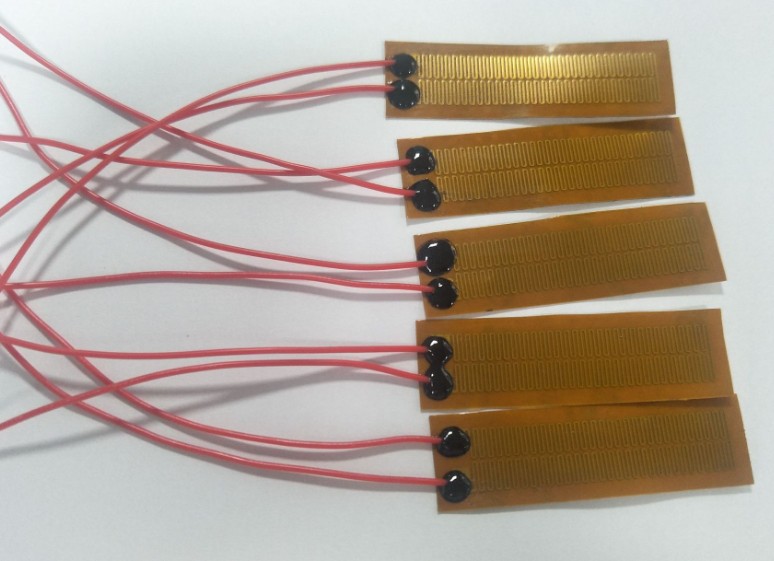

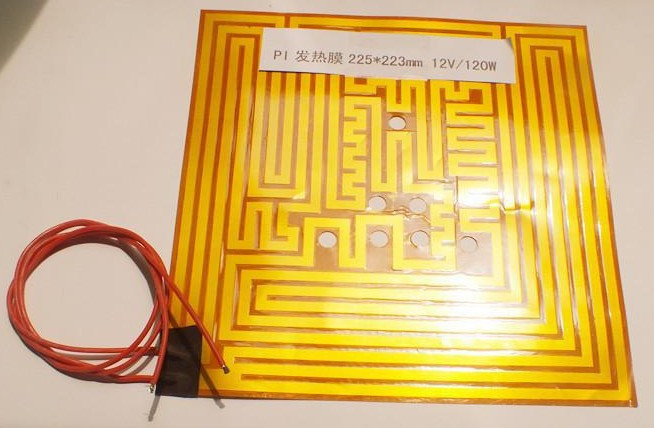

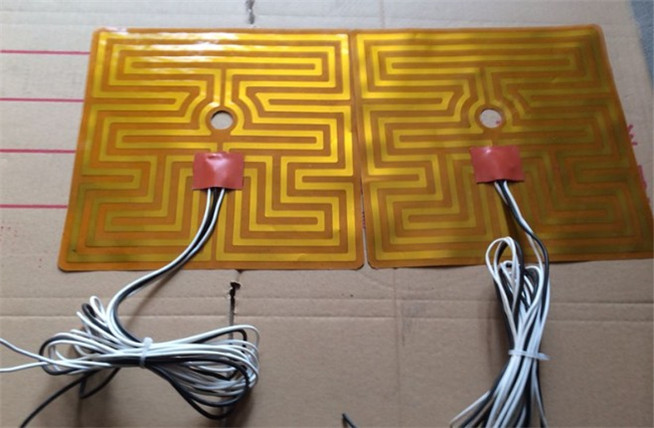

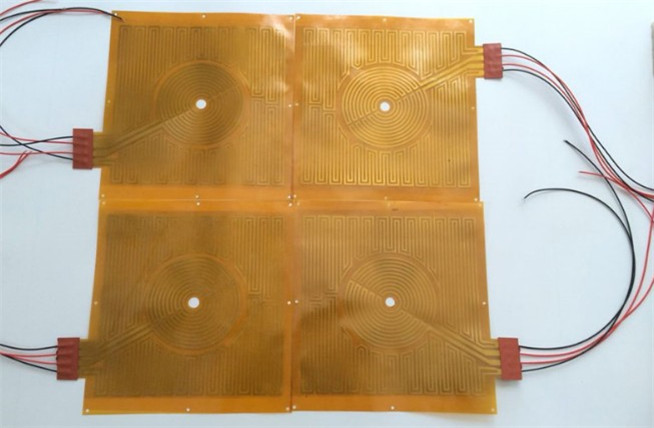

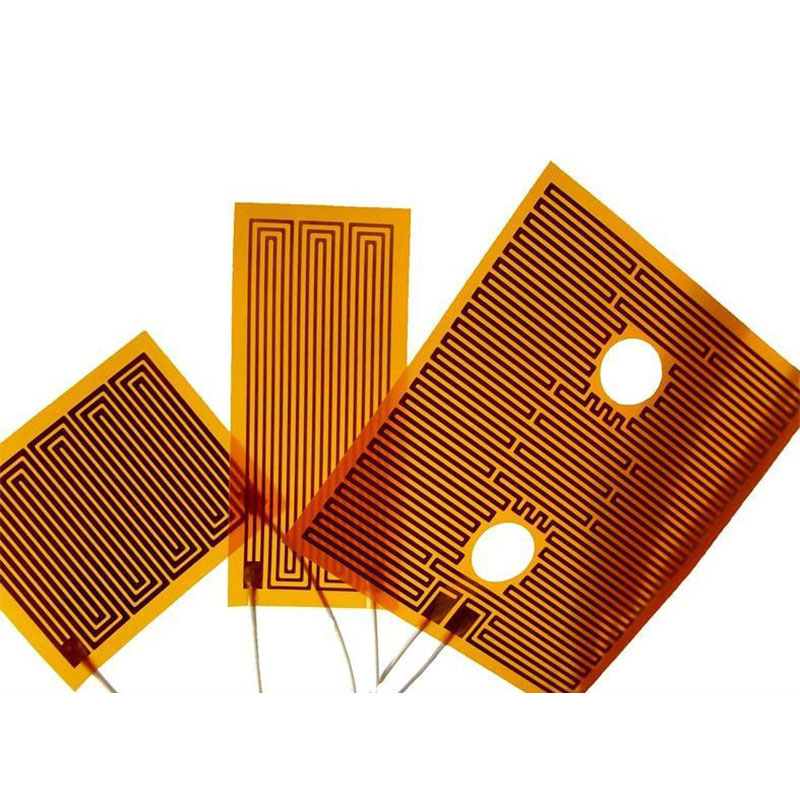

Procuct Show

Performance parameters

◆Insulation and thermal conductivity layer: polyimide film

◆Heating core: nickel-chromium alloy etching heating piece

◆Thickness: about 0.3mm

◆Compressive strength: 1500v/5s

◆Working temperature: -60-200℃

◆External voltage: customer demand

◆Power: designed according to the product use environment

◆Power deviation: <±8%

◆Lead tensile strength: >5N

◆Adhesive strength of adhesive: >40N/100mm

Application range

1. Scientific analysis instruments, such as: provide a constant temperature source for the thermal conductivity (or thermal insulation coefficient) tester, medical instruments, etc., to stabilize the operating temperature of the optoelectronic components.

2. In a deep cold environment, make the instrument and equipment reach a safe working temperature. For example: instruments and facilities such as artificial satellites, space vehicles and airplanes, as well as instruments used in high latitude areas, and instruments to prevent low temperature, such as card readers, liquid crystal displays, LCDs and other instruments.

3. Vacuum heating and baking field.

4. Heating of automobile oil pan, rear-view mirror defrosting sheet, snow removal and defrosting heating element of antenna or radar.

5. Medical care and beauty equipment industry.

Product detail pictures:

Related Product Guide:

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for Excellent quality Pi Film Heating - PI Heater Film(Thin film PCB) – Xinhui , The product will supply to all over the world, such as: Seattle, Lyon, Argentina, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a in depth mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.