Excellent quality Pi Film Heating - PET Heater Film(Flexible PCB) – Xinhui

Excellent quality Pi Film Heating - PET Heater Film(Flexible PCB) – Xinhui

Excellent quality Pi Film Heating - PET Heater Film(Flexible PCB) – Xinhui Detail:

Features

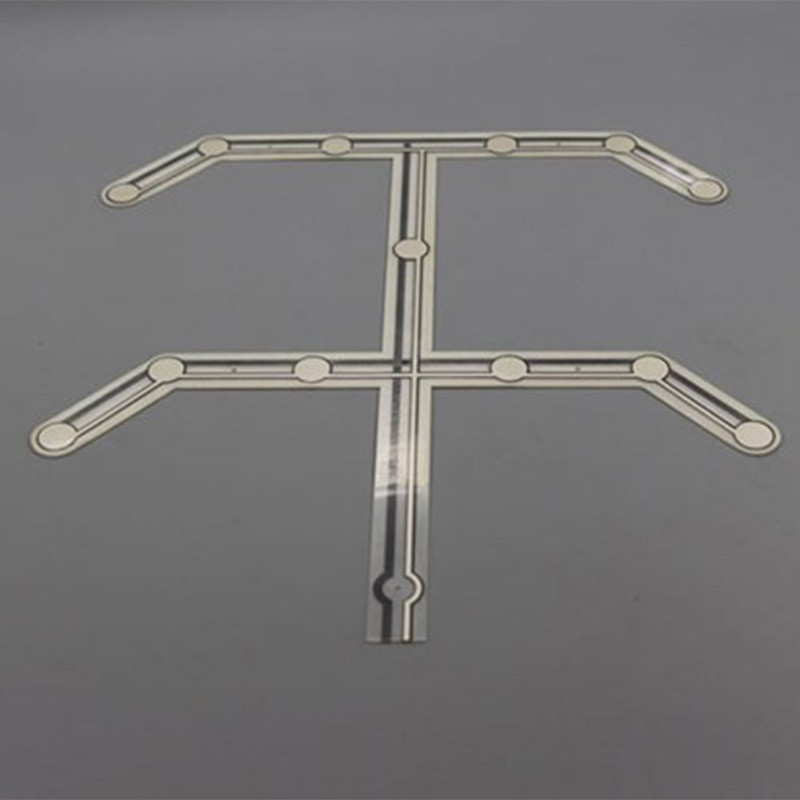

◆Thin thickness: The thickness is only 0.3mm, the surface is flat, the space is small, and the bending radius is about 10mm.

◆Various varieties: various small-area resistive circuit elements can be made.

◆Even heating: the circuit layout of the etching process is uniform, the thermal inertia is small, and it is in close contact with the heated body

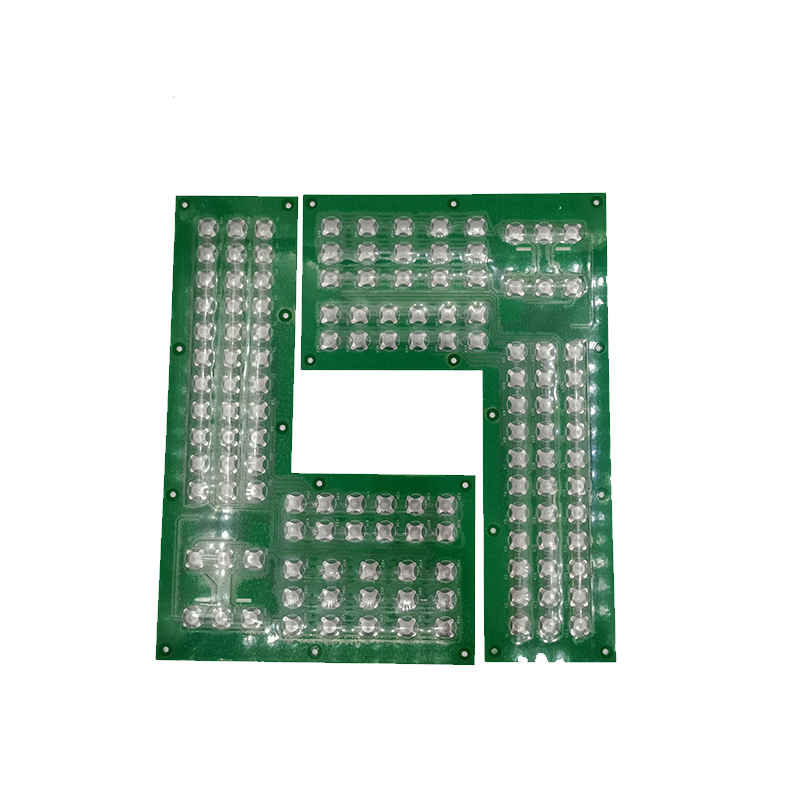

◆Easy to install: with double-sided tape, it can be directly pasted on the surface of the heated body.

◆Long safety life: Designed within 100°C operating temperature, low power load and long service life compared with other heating wire heaters.

◆Low price: The laminating process is simpler than that of PI electric heating film. It is an ideal product if the temperature requirement is not high.

Performance parameters

◆Insulation and thermal conductivity layer: PET film

◆Heating core: nickel-chromium alloy etching heating piece

◆Thickness: about 0.3mm

◆Compressive strength: 1000v/5s

◆Working temperature: -30-120℃

◆External voltage: customer demand

◆Power: designed according to the product use environment

◆Power deviation: <±8%

◆Lead tensile strength: >5N

◆Adhesive strength of adhesive: >40N/100mm

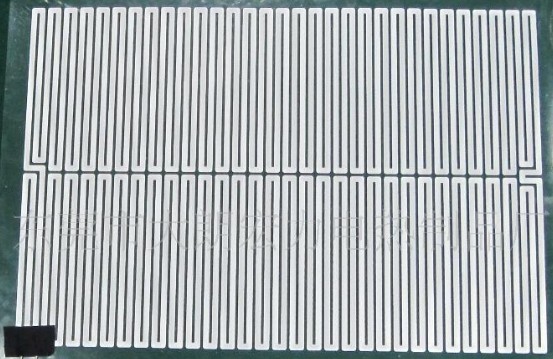

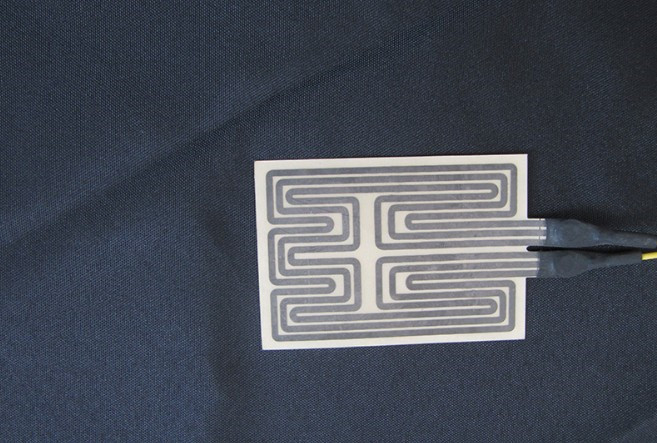

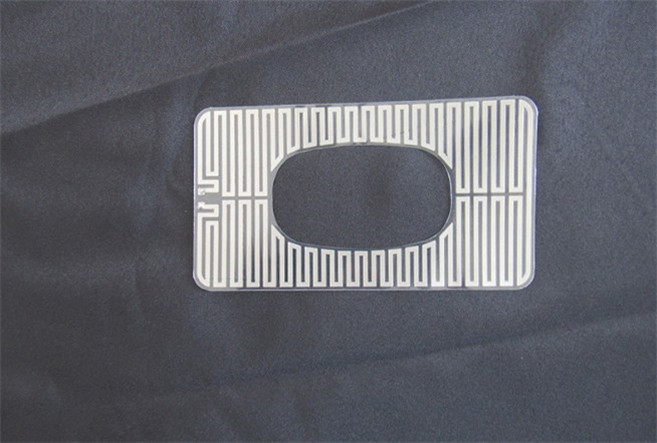

Product Show

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Excellent quality Pi Film Heating - PET Heater Film(Flexible PCB) – Xinhui , The product will supply to all over the world, such as: South Africa, Hyderabad, Philippines, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!