China OEM Membrane Switch Keypad - Film sticker(Backlit film buttons) – Xinhui

China OEM Membrane Switch Keypad - Film sticker(Backlit film buttons) – Xinhui

China OEM Membrane Switch Keypad - Film sticker(Backlit film buttons) – Xinhui Detail:

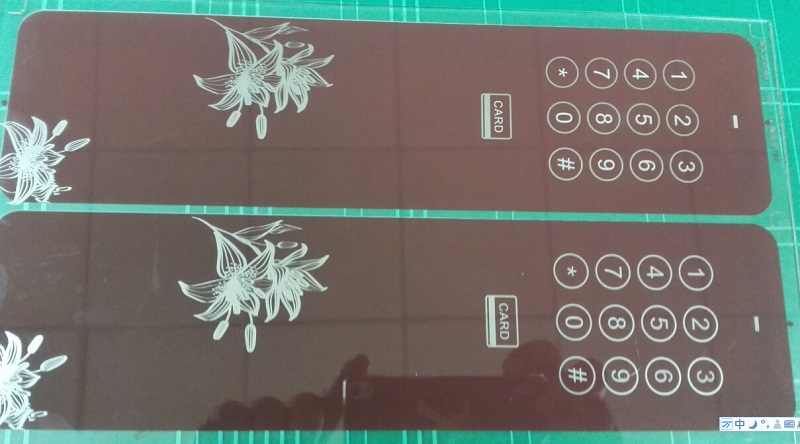

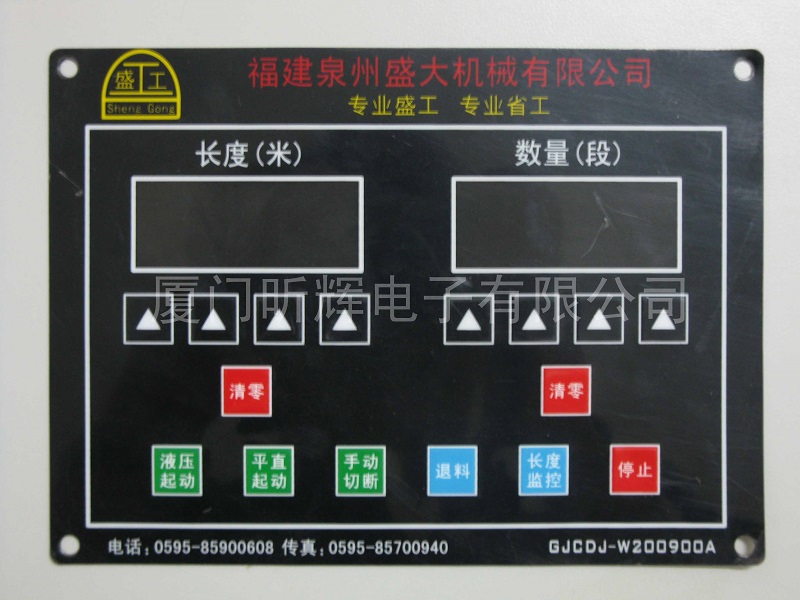

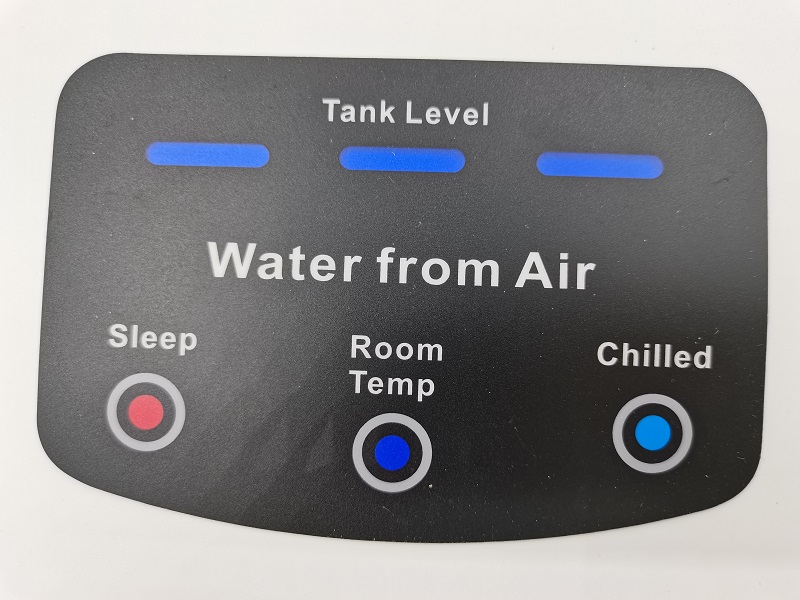

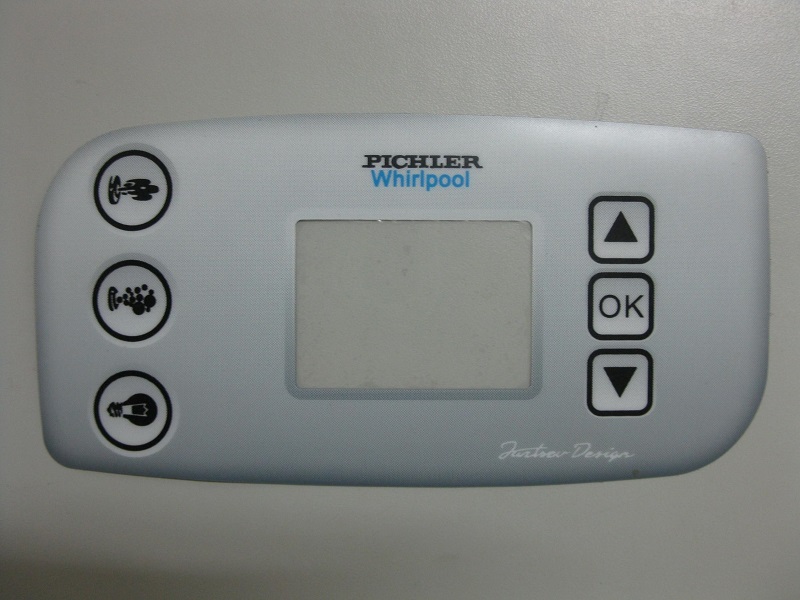

Film sticker (panel)

Product related words: film panel, touch panel, self-adhesive sticker, machine surface sticker, button panel, instrument label, equipment control mask, PET/PC nameplate, self-adhesive label, film label, film label

The panel layer is generally made of exquisite patterns and text printed on colorless transparent sheet materials such as PET, PC, etc. less than 0.25MM. Because the main function of the panel layer is to play the role of identification and keys, the selected material must have high transparency , High ink adhesion, high elasticity, high toughness and other characteristics.

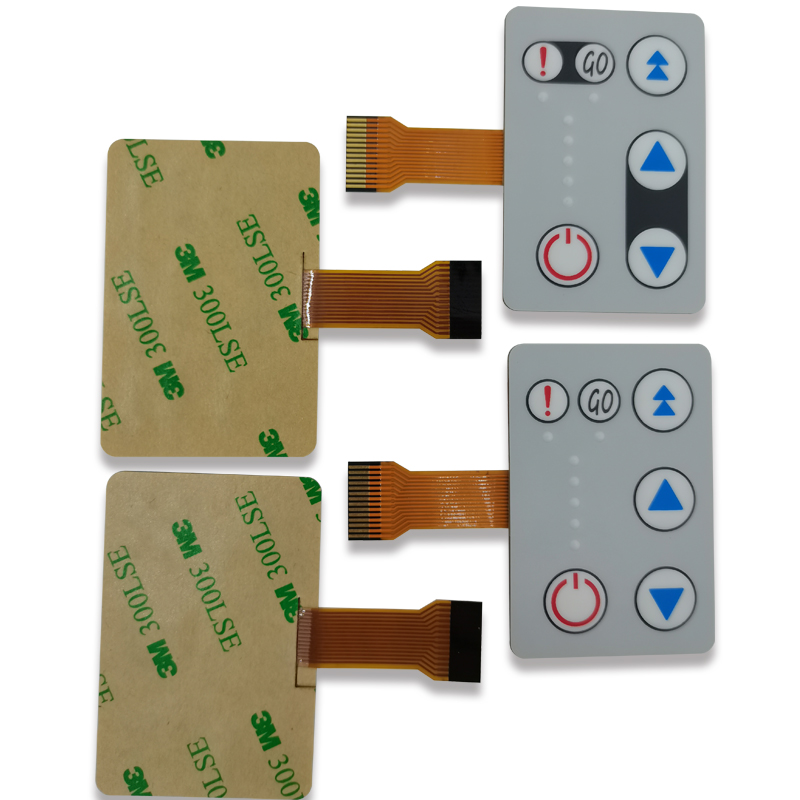

Surface adhesive layer

The main function of the surface glue is to closely connect the panel layer and the circuit layer to achieve the effect of sealing and connection. The thickness of this layer is generally required to be between 0.05 and 0.15 mm, with high viscosity and anti-aging properties; in production In general, special membrane switch double-sided adhesive is used, and some membrane switches require waterproof and high temperature resistance. Therefore, the surface adhesive must also use materials of different properties according to needs.

Related Parameters

| Membrane switch parametersameters | ||

| Electronic properties | Working voltage:≤50V(DC) | Working current:≤100mA |

| Contact resistance:0.5~10Ω | Insulation resistance:≥100MΩ(100V/DC) | |

| Substrate pressure resistance:2kV(DC) | Rebound time:≤6ms | |

| Loop resistance: 50 Ω, 150 Ω, 350 Ω, or determined according to the user’s needs. | Insulation ink withstand voltage:100V/DC | |

| mechanical propertiesti | Reliability service life:>One million times | Closure displacement: 0.1 ~ 0.4mm (tactile type) 0.4 ~ 1.0mm (tactile type) |

| Working force: 15 ~ 750g | Migration of conductive silver paste: at 55 ℃, temperature 90%, after 56 hours, it is 10m Ω / 50VDC between two wires | |

| There is no oxidation and impurity on the silver paste line | The line width of silver paste is greater than or equal to 0.3mm, the minimum interval is 0.3mm, the rough edge of line is less than 1 / 3, and the line gap is less than 1 / 4 | |

| Pin spacing standard 2.54 2.50 1.27 1.25mm | The bending resistance of outgoing line is 80 times with d = 10 mm steel rod. | |

| Environmental parametersme | Operating temperature:-20℃~+70℃ | Storage temperature: – 40 ℃ ~ + 85 ℃, 95% ± 5% |

| Atmospheric pressure:86~106KPa | ||

| Printing index index | The printing size deviation is ± 0.10 mm, the outline side line is not clear, and the weaving error is ± 0.1 mm | The chromatic deviation is ± 0.11mm/100mm, and the silver paste line is completely covered by the insulating ink |

| No ink scattered, no incomplete handwriting | The color difference is not more than two levels | |

| There shall be no crease or paint peeling | The transparent window shall be transparent and clean, with uniform color, without scratches, pinholes and impurities. | |

Surface adhesive layer

The main function of the surface glue is to closely connect the panel layer and the circuit layer to achieve the effect of sealing and connection. The thickness of this layer is generally required to be between 0.05 and 0.15 mm, with high viscosity and anti-aging properties; in production In general, special membrane switch double-sided adhesive is used, and some membrane switches require waterproof and high temperature resistance. Therefore, the surface adhesive must also use materials of different properties according to needs.

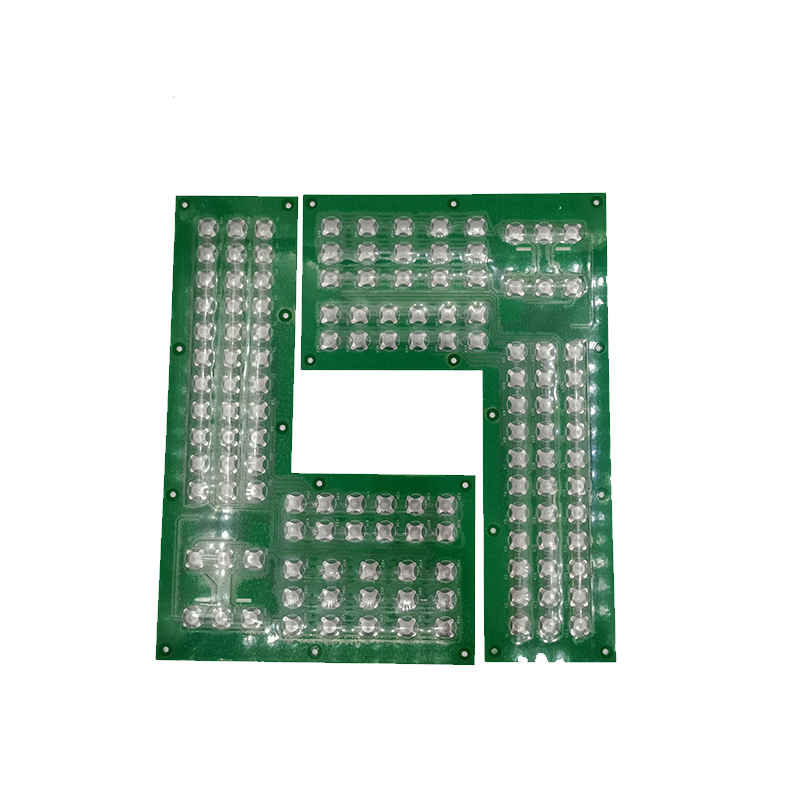

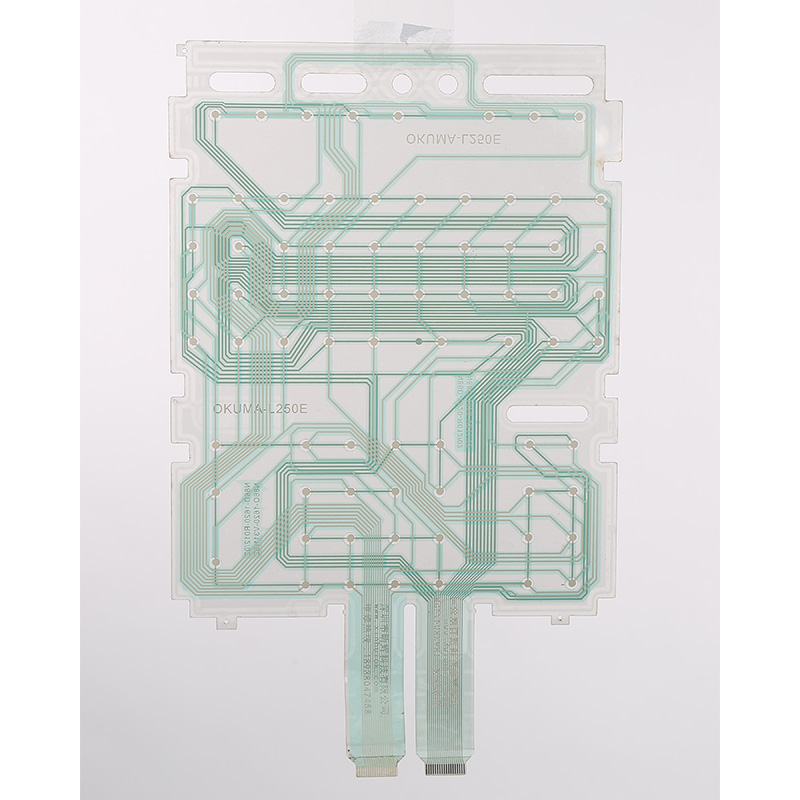

Product Show

Product detail pictures:

Related Product Guide:

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for China OEM Membrane Switch Keypad - Film sticker(Backlit film buttons) – Xinhui , The product will supply to all over the world, such as: Saudi Arabia, Adelaide, Bangalore, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.